Electricity and air pressure are the two power sources that power the bulk of America’s workshops. Just as we have circuitry with easily accessed outlets all around the shop, so does our shop have air-lines with quick-connect hoses positioned at strategic intervals.

Air compressors are ubiquitous. From the corner gas station with a 50-cent coin slot to the small cordless air compressor that you use to inflate soccer balls and bicycle tires, these devices are everywhere.

They come in every shape and size. Some compressors are used to power massive air tools such as jackhammers and sandblasters. Contractors use Air compressors on every job site in America, and it is air power that has built most of our homes.

Advantages of Air Tools

There are four unique advantages of air tools.

Smaller Footprint: The first advantage is that pneumatic power eliminates the need for tools to each possess its own electric motor. This lack of an individual motor dramatically decreases the tool size and makes it easier to fit the tools into those hard to reach places. This maneuverability is one reason why dental devices are all pneumatically powered.

Less Spark: Electric motors create a spark which is not ideal when working around flammable materials. Pneumatic tools don’t have this sparing issue, making air tools safer for use in the automotive world.

More Power: In comparison to the size of the motor that would be required to create the same amount of torque with an electric motor, these tools are able to deliver considerably more torque in a smaller footprint. An impact wrench can provide as many foot-pounds of torque as a Locomotive!

Better Longevity: Electric motors have brushes and windings that wear down. As long as pneumatic tools are regularly oiled, they should last for years (if not decades) of use.

Air Compressor Types

There are several types of air compressors:

Reciprocating compressors use a reciprocating piston that is moved up and down by a rotating crankshaft, similar to how a car engine works. These are what we see most commonly in.

Rotary Screw air compressors use two meshed screw drives that constantly spin to force air down the shaft from the larger, least-compressed grooves into the narrow, more compressed grooves. Industrial purposes often use rotary screw air compressors.

Rotary Vane Compressors use a rotor with a number of spring-loaded blades. This rotor is off-set inside a cylinder and spins to move air from the larger area of the cylinder down into the smaller side. This movement of the off-set rotor compresses the air. Rotary vane compressors are some of the oldest compressor designs and are commonly used for industrial uses such as wastewater treatment or water aeration.

There are other compressor types, but these are the most common.

All air compressors work on the principle of moving air from a larger space into a smaller space.

This discussion will focus on reciprocating air compressors.

How Do Positive Displacement Reciprocating Air Compressors Work?

(Do You like how I used a title that makes me sound smart?)

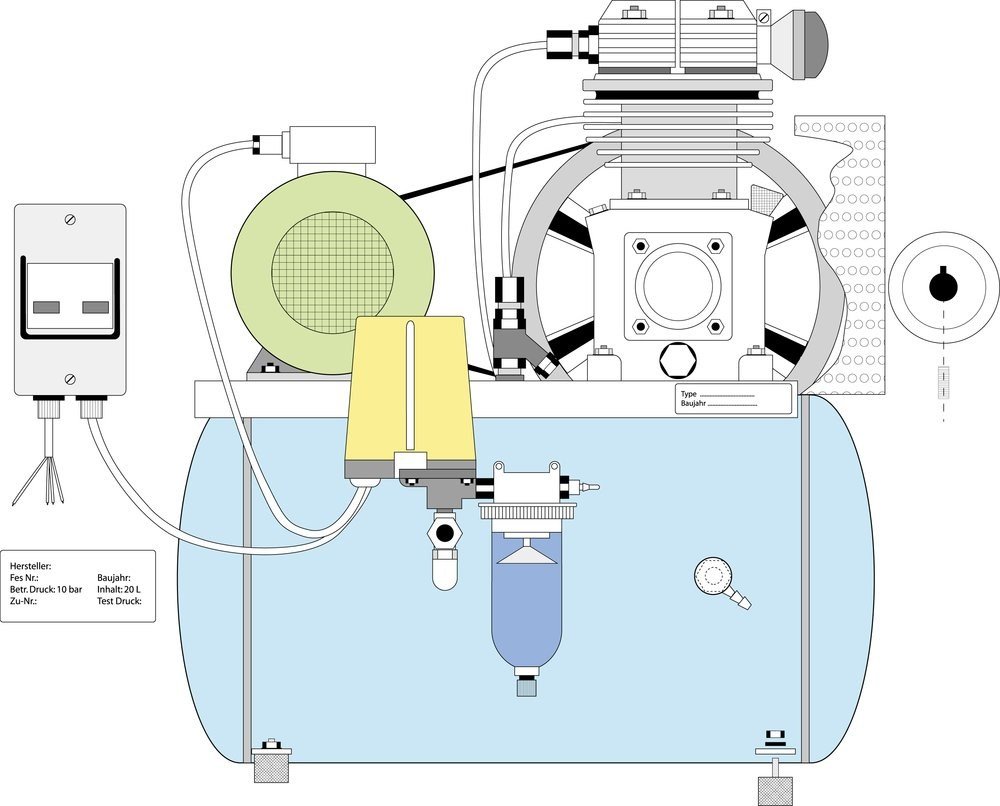

The standard compressor in your garage is going to work in a manner similar to a vehicle engine. The electric motor (sometimes a gas engine) spins a crankshaft that moves the connecting rod up and down, which causes the piston to move inside the compression chamber.

On the downstroke, the inlet valve opens and admits air from the outside. These piston compressors are vulnerable to dirt, so there will be an air filter on the outside that it pulls the air through.

On the upstroke, the inlet valve closes, and the unloader valve opens, allowing the compressed air to flow through to the tank. As the piston moves downwards, this discharge valve closes, trapping the compressed air in the storage tank and the inlet valve opens, repeating the cycle.

It is a straightforward yet effective system.

Important Parts Of An Air Compressor

Pressure Switches

The pressure switch measures the amount of pressure building inside the tank and connects to the motor. As the pressure builds, this switch will allow the pressure to build to a preset point called the cut-out point. At that point, the switch sends a signal to turn off the motor, and the compressor shuts off to prevent overloading the tank.

The pressure switch then monitors the air use, and when the tank pressure dips below a preset point (called the cut-in point), the pressure switch signals the motor to re-engage.

This difference between the cut-in point and the cut-out point is called the “pressure differential.”

On most consumer and contractor grade air compressors, the owner cannot adjust the pressure differential between cut-in and cut-out. However, the overall range can be adjusted up and down. We have a guide for adjusting your pressure switch.

Overload Valve

An air compressor explosion can be deadly. Accordingly, the compressor’s steel tanks must meet certain industry standards. Well-maintained tanks rarely explode.

There is also a safety bypass valve called the compressor relief valve. If the pressure switch fails to shut off the compressor, the compressor relief valve opens, releasing excess air until it reaches a safe threshold, at which point the valve closes again.

Air Regulator

As the air leaves the machine for use, there are two gauges and a large knob which denotes the air regulator.

The first pressure gauge measures the pressure that is in the tank. The second gauge shows you how much PSI is flowing out of the regulator. You can turn the large knob to open the regulator for more PSI, or down if you are using a tool that does not require as much pressure.

How to Adjust your air compressor regulator.

Heat As A Limiting Factor

You may have noticed that most compressors only offer 120 to about 150 PSI (Pounds Per Square Inch) as the highest PSI ratings.

The reason for this has to do with heat.

When the piston moves against the air, there is an incredible amount of friction and heat. This heat hinders the compression process, making the compressor less efficient.

Additionally, if the compressor was required to lift the air to a higher PSI, it could create a more explosive situation from the hotter, compressed air.

Accordingly, compressors that need to meet higher air requirements use a two-stage compression model discussed below where the air is compressed in cylinder one, cooled briefly, and the compressed in cylinder two.

Many compressors have a flywheel that either drives a fan or acts as a fan to help move air across the valve head.

One Cylinder, or Two?

Many compressors offer two compression chambers.

Single Stage

This is the most common design. A single cylinder delivers the air pressure to the storage tank. For most tasks, this design is more than adequate. There are a few portable air compressors that use the two cylinder design, but most of them are single-cylinder.

Dual Chamber

This system is still a single stage compressor, but it has dual, single stage compression chambers. Dual chambers allow a compressor to build air volume more rapidly. This design can help a compressor deliver higher airflow to keep up with demanding CFM (Cubic feet per minute) requirements.

Dual Stage Air Compressor Setup

This model also has two compression chambers. However, one is sized larger than the other. In this setup, the first compressor chamber raises the pressurized air to around 150 psi. It is then sent over to the second chamber where it is compressed to an even higher level. Two-stage compressors are perfect for applications that require higher pressure levels.

Important Compressor Terms and Specifications

If you are shopping for a compressor, you will notice a lot of confusing ratings. Let’s talk about them quickly.

Horsepower: This discusses the engine horsepower. Overall, this isn’t extremely helpful as you could have a large motor paired with an inefficient compressor. The other ratings are more useful.

Air Flow: The standard measurement for the volume of air is standardized in Cubic-feet-per-minute or CFM. Nail guns only need about 2-3 CFM. Spray guns for automotive painting need 14 CFM (unless you are using a low volume high-pressure spray gun, in which case about 4 CFM should do.) We have a list of the common tool types and their Air volume requirements. Since CFM is affected by the air that the compressor is operating in, there is a standardized calculation of SCFM (standard cubic feet per minute) which is CFM at sea level with 68 degrees Fahrenheit temperature and 36% relative humidity. SCFM ratings are provided at 90 PSI. If the PSI increases, the SCFM decreases and vice-versa (Bernoulli’s principle).

Pressure: The measurement unit for pressure rating is pounds per square inch or PSI. For example, framing nailer should use about 3 CFM and 90 PSI. Due to Bernoulli’s principle, when the air pressure (PSI) is decreased, the volume of air (CFM) is increased.

Power Source: Small portable air compressors should only draw 15 amps to ensure that they can be plugged into just about any outlet. If you buy a compressor that requires 20 amps, make sure that your circuitry is designed to handle it. Larger, 20-gallon and 60-gallon compressors may require more power or a 220volt circuit.

Air Tank: The air storage compressor helps you plan on how much reliable air flow with which you will have to work. A 6-gallon or 8-gallon air tank might be great for building a house, but insufficient for running an air impact wrench. A 20-gallon tank compressor will not only offer a bigger tank, but it is likely paired with a larger compressor pump as well. Something like that would be ok for a single-mechanic shop that only needs to power impact wrenches. For the dedicated shop compressor, something like a 60-gallon compressor will provide an endless reserve of air flow and possible a two-stage compressor pump.

Oil-free vs. Oil Bath Compressors

I discuss this briefly in my list of the best compressors and then have an entire article devoted to oilless vs. oiled.

Light-duty compressors and some contractor models offer a Teflon-coated piston that requires less oil. These are only designed to last about 2,000 hours (or 18 months of heavy use).

Heavy-duty compressors use an oil bath to lubricate their systems and tend to last about 15,000 hours.

Getting The Correct Air Compressor

Choose your compressor based on the type of uses you will have for it. Our chart on the air requirements based on pneumatic tool type is an excellent place to start.

Skip to content

Skip to content