You want your compressor to last as long as possible.

How often do you need to drain it? Can you leave air in the compressor tank when you aren’t using it?

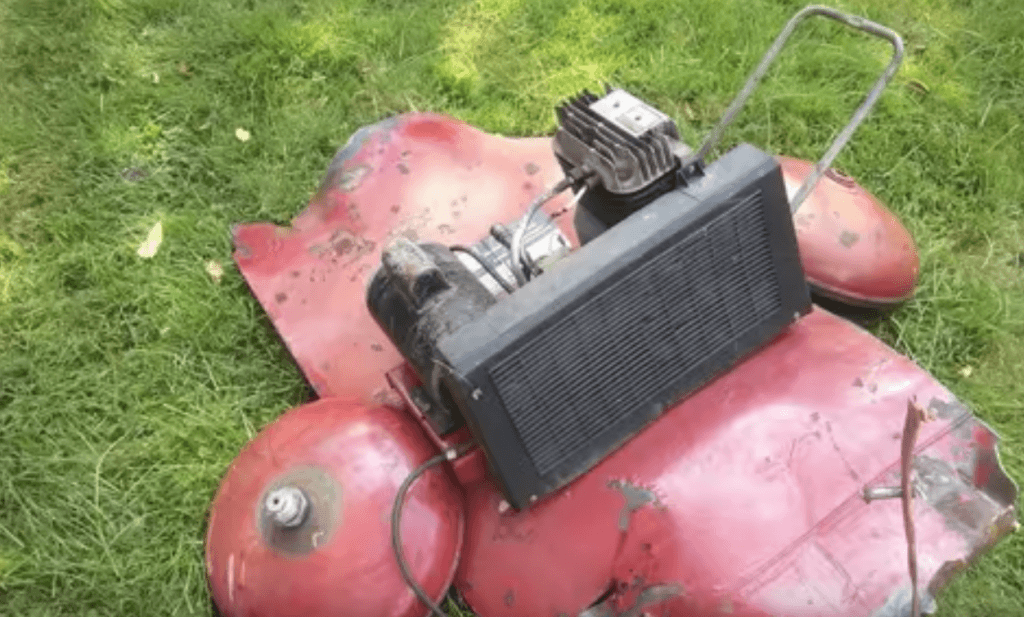

Growing up, my dad had an air compressor he purchased at an auction for $15. We used the heck out of that thing and only drained it about once a year. Once the compressor started creating leaks at the connectors. As it started leaking air, my dad would finally turn it off between uses.

But when it comes to abusing air compressors, my family definitely set an example of how NOT to do it.

Listen, a poorly maintained air compressor can explode. So this is an important question.

Here’s everything you need to know about leaving compressed air in your air tank.

See Related: Adjusting Your Air Compressor Pressure Switch

Can You Leave an Air Compressor Full?

When you fill your air compressor tank, can you leave it full?

Technically, leaving an air compressor with a full tank is perfectly safe. However, all air compressors should be drained at least once a day (on days when they are used) to prolong their lifespan, remove condensed water from the system and protect pneumatic tools.

Countless hobbyists, mechanics, and even machine shop foremen leave an air compressor pressurized without anything going wrong, even for longer periods.

That said humidity matters. In the southern states, the humidity can be extremely high during the summertime, forcing daily draining.

The air compressor regularly has a drain valve on the tank regularly opened to release water. Open drain valves allow the accumulated moisture from the air inside the compressor’s tank to flow out.

See Also: Do Air Compressors Run Out Of Air?

Why is it Necessary to Drain the Air Compressor?

No matter what you use your air compressor for, you should drain tank completely of moisture at the end of your workday.

In the ambient air, there will always be some water vapor content, and this water vapor builds up when the compressor pump creates compressed air and pumps it into the air tank (alongside all that water vapor).

To drain the air pressure in the tank, the drain valve should be opened slowly to relieve the air pressure in the tank. In larger models, there will be much more compressed air and much more water vapor. My experience is that on smaller air tanks, tipping the tank towards the drain plug can let you get that last little bit of water out.

In large air compressors, draining water is a daily task that needs to be done to extend the operating life of the compressor tank. Most air compressors with larger duty cycle ratings may have an auto drain valve on the compressor, but this isn’t a guarantee, and the drain valve still needs to function correctly to receive the benefits, so they should be inspected regularly.

You can also purchase an after-market automatic drain valve for your compressor that automatically flushes the air out at the end of every workday.

The 3 Primary Reasons to Drain Air Compressors Regularly

The biggest reason to open the drain valve on your air compressor tank is to prevent moisture build-up in the air tank.

Even though most companies now coat the inside of their air compressor tanks with special corrosion-resistant coatings, exposure of metal to water over an extended period will still cause rust and corrosion in the pressure tank.

Another reason to drain your air compressor is that you will be protecting your pressurized air tools. Each air tool that you connect to your tank will be fed the pressurized air and water from that tank. Unless you drain the air compressor, that water can cause rust inside of the power tools you use.

It saves you money in tool replacement costs to have a clean source of air.

This damage is insidious. The pneumatic tools are fed tiny droplets of water from the air compressor, and that water can damage the tiny inner workings. Tiny internal items like air cylinders and valve components can rust easily.

The bottom line is that you don’t moisture in your work. Woodworking with wet pneumatics can warp the wood. Airbrushing with water in the line can ruin an entire project. Sand blasting with a high water concentration can cause clumping and excessive pitting of the sandblasted item.

How Often Should I Drain My Air Compressor?

How often you drain your air compressor will generally be determined by the usage it sees. Another big factor will be the local weather conditions and ambient moisture.

If the air compressor was used in a very humid environment, the draining may need to happen more often, because the compressor will be pumping more moisture into the tank when in use.

In general, the more often your compressor compresses air, the more water it will compress as a result. In most situations you should drain the tank every day the compressor is used.

Should I Drain My Air Compressor After Every Use?

If the air compressor is used daily, you may only need to open the drain valve every few days, or whenever the tank is no longer pressurized.

However, if the air compressor is only used on rare occasions, the drain valves should be opened after every use.

How to Drain Your Air Compressor – A Step-by-Step Guide

Here’s a step-by-step guide for draining your air compressor’s air tank. While the procedure will be largely the same, you can check the manual provided by the manufacturer to ensure your process is the same.

Step One:

The first thing you need to do is power down your air compressor, or disconnect it from the power source if it cannot be shut off. In some situations, this may mean throwing a local circuit breaker, and if your air compressor is large enough, it may even have a dedicated breaker nearby.

Step Two:

Locate the safety release valve, which is usually easily found due to the ring used to pull it open. Pull the ring and depressurize the tank.

When you pull the ring, it will often remain in the “pulled-out” state until the pressurized air is low enough that the spring can close the valve again.

This will be loud and often startling the first time you do it. When the gauge reads less than 10psi you can let go of the ring. It should snap back in when the pressure is low enough.

If your compressor does not have a safety relief valve, you can move directly to step four.

Step Three:

Now you can locate the drain valve at the bottom of the tank. They will often have a wingnut or similar thumbscrew to open them easily without using tools. Larger air compressors will have a ball valve that can be turned a quarter-turn to open or shut.

Step Four:

Once the moisture has completed draining from the tank, you must remember to close the valves or the tank will not hold pressurized air. There is no huge danger to this, but it can be frustrating to have the compressor running for ten minutes before you realize no pressure is being generated.

The compressor can recharge at that moment if you would like, and then it is fine to leave air in it overnight so that it is ready for your use the next day.

See Related: What To Do When Your Compressor Will Not Build Pressure

Conclusion

If you only use your compressor rarely for the odd project here and there, you’ll want to make sure you empty it after each use.

Remember: cut the power, drain the moisture, and then close the valve so it can hold air once again.

Skip to content

Skip to content