Our phones are more powerful than the computers used to put a man on the moon.

And all we use it for are endless games of Snake, Clash of Clans (yes, I’m still playing), or for getting spied on by Facebook.

Wouldn’t it be cool if we could tap into that power for something a little more practical?

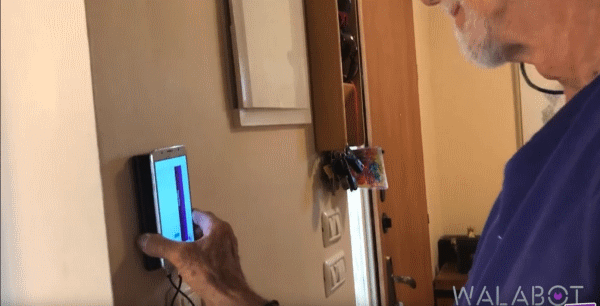

I recently got a call from one of my contractor buddies. “Have you heard about this new app thingy that lets you see through walls? Looks pretty cool!”

Like any other home remodeler, I was intrigued.

It turns out that there are a few of these devices that are designed to work with your smartphone. Of those, Walabot and Flir One are two brands that are rapidly gaining market share. I enjoy using the Walabot Stud finder app for my DIY, handyman, and home remodeling work. The Flir is more expensive, so I borrow my buddy’s when solving home comfort issues.

In the next two minutes, I’m going to give you a quick overview and comparison to help you make the best choice. Tool Tally makes tool buying easy!

Walabot DIY Versus Flir Comparison Chart

Walabot

- Uses Radio waves to detect and identify objects such as pipes wires, and studs in a wall

- Must be held directly against a wall

- Requires the Walabot App

- For Android Phones Only

- It is ideal for identifying objects on walls.

Flir One

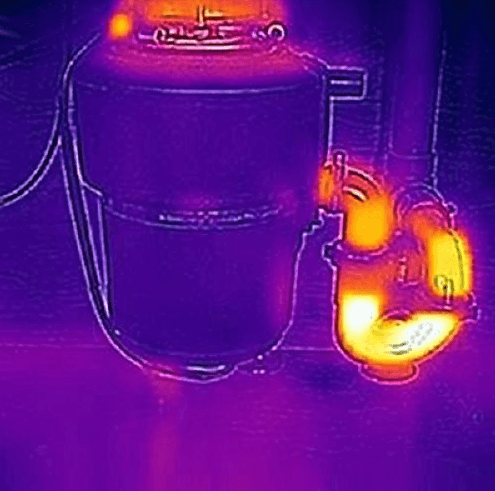

- Uses an Infrared camera to detect hot and cold spots in a wall, including hot or cold pipes and lack of insulation

- It can be used while standing away from the wall

- Available for both iOS and Android

- Ideal for identifying hot and cold spots.

- Commonly used by professional contractors to diagnose house envelope issues.

We’re talking about two entirely different devices here. One of them uses radar; the other uses an infrared camera. They both see through walls, and they both can help identify objects that are in walls. The Walabot is good for detecting studs, pipes, and wires. The FLIR One is good for detecting heat signatures but not good for finding studs.

Honestly, I feel the Walabot feels a tad gimmicky for my old-fashioned tastes. Check out the Bosch Multi-scanner that can see through 4.75″ of cured concrete or brick! That said, Walabot has really stood the test of time now and has continued with its app updates and responsive customer support. So you won’t go wrong buying one.

Walabot DIY

The Walabot is a sensor that attaches to your phone and allows you to see inside walls to find PVC pipes, metal pipes, wood studs, metal studs and even termites (cool right?).

The Walabot handheld scanner is about the size of a cell phone and easily interfaces with Android smartphones.

If you frequent DIY sites (like ours), you’ve undoubtedly been targeted with ads for this wall scanner. They show someone sliding their phone along the wall and being able to identify studs, plumbing, and electrical wiring miraculously.

The Walabot stud finder works, especially on sheetrock walls. However, what no one talks about is the frequent calibration that it requires. Calibrating the device requires you to make large circles on a wall so it can get a read of the different signals. Only then will it start to detect studs accurately.

However, if you stop scanning, say to drill a hole, sometimes it requires you to recalibrate. It is likely that you will end up spending as much time calibrating as you will working.

It is common to need to calibrate any stud finder and provided that you are working on a home with standard sheetrock, the Walabot is going to work almost well as any other basic stud finder on the market. You’ll have the added advantage of being able to identify what you are looking at in the wall visually with its 3d Imaging. For the tech-savvy homeowner, it makes hanging pictures and shelves much easier.

One of the cool features of the Walabot scanner is that in imaging mode, you can see a large mass of termites in a wall. This insect detection mode can make it handy when trying to identify the height of termite damage in a wall if there is currently an active infestation.

The Walabot DIY is an excellent stud detector for the smartphone age. With time, it’s going to be an industry leader. But it isn’t (yet) the next breakthrough in wall scanning than most of us hoped it was.

Finding Termites

On my first home purchase, we found extensive termite damage underneath the house and wanted to know how far up the walls the damage went. We removed a foot of sheetrock along the base of several walls to check the studs. It was pricey but worthwhile for our peace of mind.

With the Walabot, Imaging Mode can detect heat signatures like mice and termites. I think that it is pretty cool, but it requires an active, untreated infestation to work.

Every time I’ve had an infestation in one of my rental houses, I’ve called the pest company immediately and forgot to test this tool on it. So I have yet to try out this handy feature.

Flir One

Flir One is a thermal camera for detecting heat signatures. It plugs into the bottom of an Android phone or iPhone (you must purchase the correct version for your phone type).

Flir One is now in the fourth generation of its product. They’ve worked out the kinks (not that their first product had many) and are moving forward to creating the best smartphone-compatible infrared camera.

Unlike the Walabot, the Flir One Pro is useful for detecting heat signals. If you need to find a water pipe in a wall, you can run warm water through it, and the pipeline will light up nicely on your screen.

Most home contractors find that the FLIR is handy for thermal imaging and locating spots where heat transfer is occurring. It can allow you to quickly identify warm spots and cold spots, stopping thermal loss and fixing major efficiency problems.

Homeowners with the diy project of home efficiency will find that the Flir offers an insane amount of data in seconds. It is a tool that is designed to help you use your smartphone to lower your electric bills.

The Flir One is surprisingly accurate and versatile as a thermal camera. We’ll do a more in-depth review and camera comparison on it soon.

However, it won’t detect wood studs with enough accuracy to drill into them.

The Flir One Edge Pro is such a handy tool that many contractors and home inspectors keep it in their toolbox with their other hand tools.

It is especially handy for those involved in HVAC repair. It can also help visualize wet drywall from broken pipes or roof leaks to uncover the underlying reason.

Can a Flir One Detect Electrical Wires? A common question is whether a Flir can detect electrical wires. If the wire is under heavy load, it may be able to detect the heat from a wire. If there is a short in the circuitry or a circuit box, the Flir can pick up on those hot spots. For reliable detection or wires inside a wall, you are better off going with the Walabot or a Multi-scanner.

Neither device gives you x-ray vision, but the Walabot is an industry-leading reimagining of the traditional stud finder, and the Flir is a new thermal imaging device that should have competitors worried.

Skip to content

Skip to content